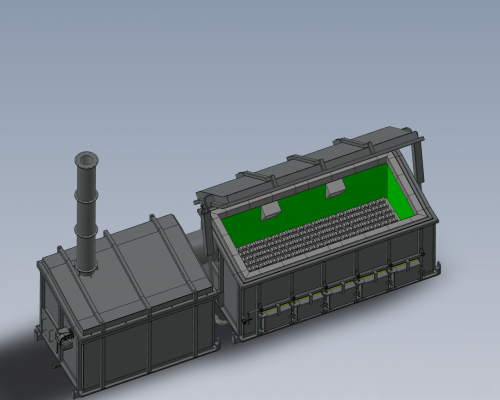

RAPID1000

Specification Summary

Parameters

Value

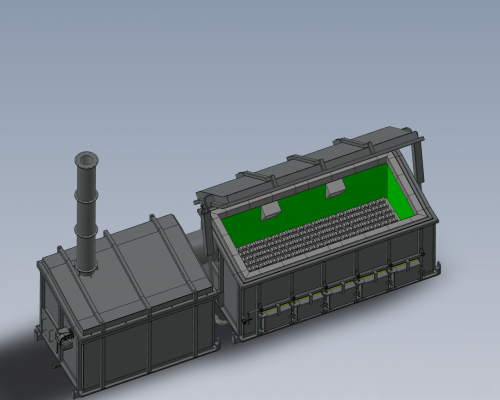

Volume

5.1 m³

Loading Chambers Size

3710 x 1510 x 1125 (at its peak)

Loading Method

Top

Refactory Thickness

190mm

Gas Retention Time

2 Seconds Seconds

Afterburn Complies with EU Legislation

Yes

CE Certified

Yes

The RAPID1000 is one of the most robust, reliable and thermally efficient large scale incinerators on the market.

The Rapid

The Addfield Rapid is a uniquely designed high capacity forced draught incineration machine incorporating pre-heated combustion air. As with all Addfield equipment the Rapid has been designed using “CFD Modelling” Computational Fluid Dynamics software, this advanced software is also used to design petrochemical plants and F1 racing cars. All Addfield machines the same basic design principles have been applied to build the most robust, efficient and reliable system available.

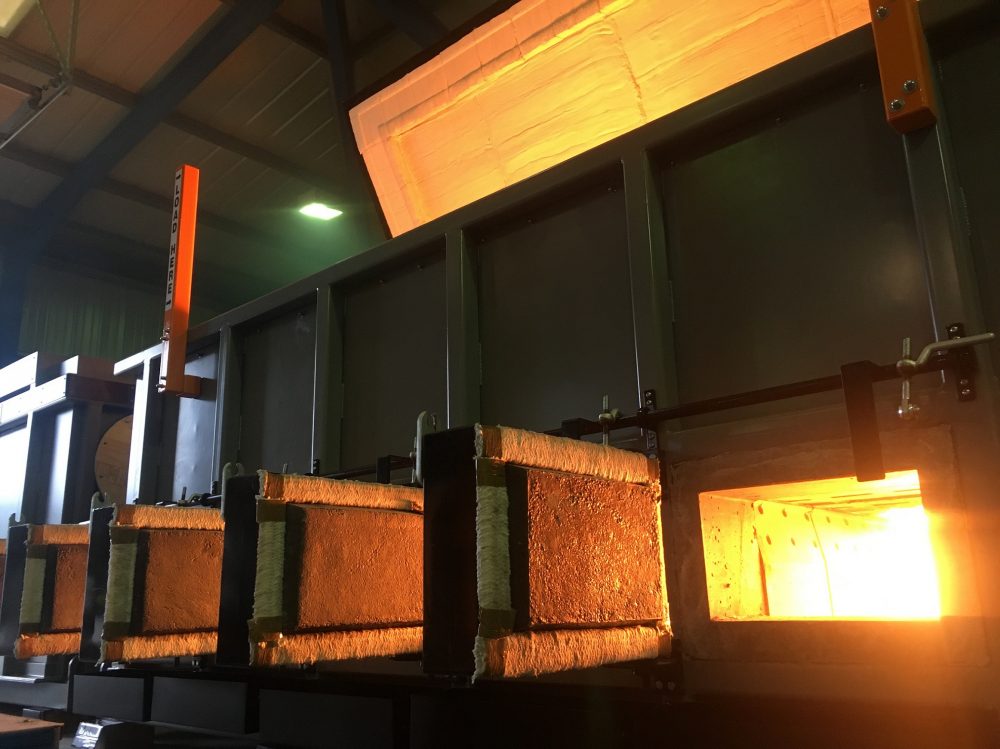

The Loading Method

Loading can be carried out either mechanically or manually through the vertical opening hydraulically operated lid, the hydraulics are fitted with multi-stage actuators that not only give speedy operation but also incorporate soft initial opening and soft final closing.

De-Ashing

The ash removal will be manually through the front ash doors, a full set of de-ashing tools are included with every Rapid machine. To de-ash simply push the de-ashing button on the control panel, this will isolate the lower burners to allow ash doors to open for ash removal.

Combustion System

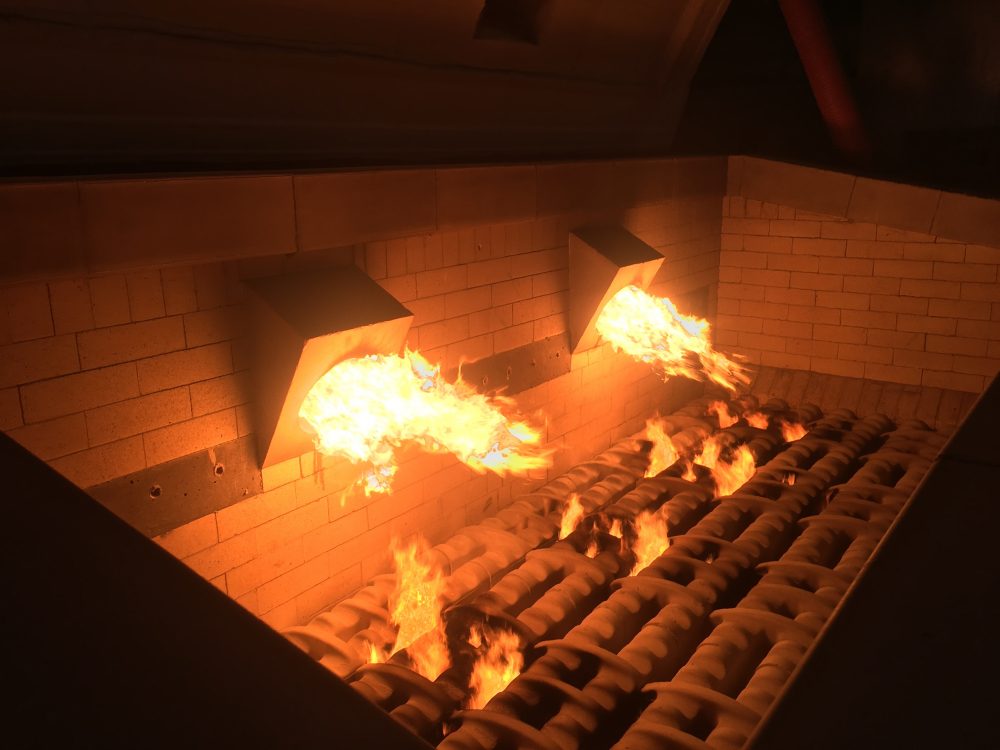

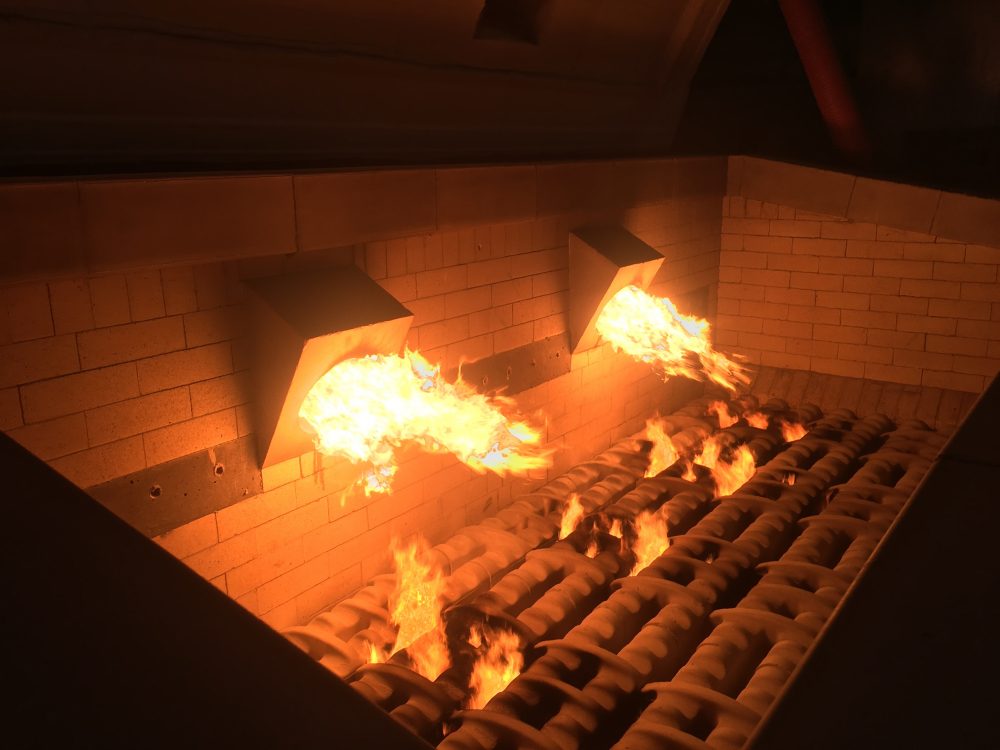

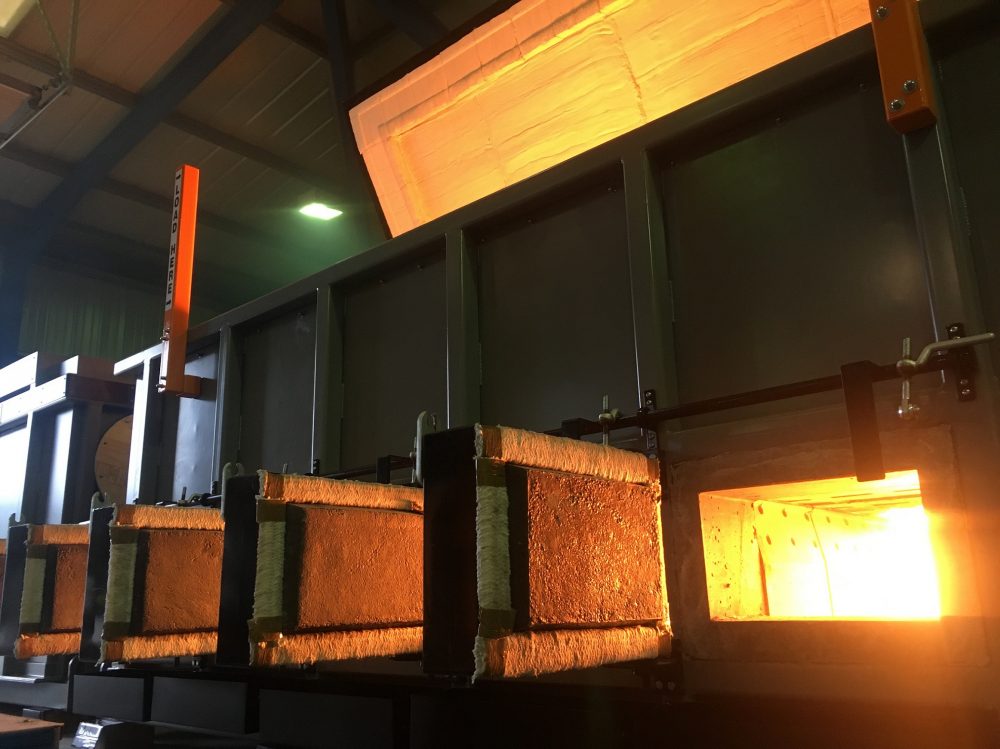

The system is complete with 9 (high/low) pulse fired burners with a potential total KW rating of 2250kw/hr ensuring even the lowest calorific value waste is destroyed 100%. Although the Rapid has a large potential KW rating it is unique with its balanced pre-heated combustion air system. This system utilises its pre-heated air along with the calorific value of the waste stream to efficiently destroy waste using minimal fuel. Combustion air is forced through the hot lower refractory structure and into the open grate where the main combustion takes place, this design actively accelerates the combustion process with production rates in excess of 500kg/hr.

Refractory Structure

The 190mm thick refractory lining of the Rapid has been specifically designed to be thermally efficient and to combat the arduous conditions that the machine will be subjected to during its operation. The main walls of the machine will be lined with our signature design of low porosity, spall and thermal shock resistant refractory bricks. The insulation system within the structure is a combination of high-temperature insulation bricks and microporous board insulation.

The complete primary combustion chamber is capped with the Addfield signature bolt-on impact-resistant pre-cast blocks, these have been designed to be easily replaceable In the event of damage. The material used in the manufacture of these blocks has been engineered to withstand the thermal shock and mechanical impacts during the loading process.

Open Grate Heath Design

The Rapid’s unique hearth design consists of super duty refractory hearth rafts rated 1760deg.C, these rafts have been designed to automatically shed ash that sits on top of them. This unique design minimises the ash build-up ensuring reduced future maintenance and increased production time. Our materials used to manufacture these rafts have been specifically formulated to withstand hot impact loading during operation, thermal shock and are low porosity to withstand liquid penetration.

- British Designed.

British Built. - World leaders in

incineration technology. - Unrivalled build quality

& machine longevity. - Distributed to more

than 140 countries. - Environmentally

Responsible. - Trusted partner with

40 years experience.