Taking care of Medical Waste in Kuwait

After more than two years in the making, and taking place during one of the most challenging manufacturing times in memory due to the impact of the Coronavirus. We were immensely proud to formally hand over the controls to our latest and largest medical waste installation in Kuwait, with a processing capacity of 24 tonnes per day.

Completed on behalf of MRC, Kuwait’s largest recycler and leading eco-industrial company, which specialises in providing sustainable solutions to waste management. Operating recycling services where possible and ensuring safe disposal of hazardous and non-recyclable waste through incineration when not. This project was jointly funded with the Ministry of Health in Kuwait and was for an incineration facility capable of disposing of huge quantities of clinical, medical and liquid waste every day.

Destined to be a part of a network of disposal centres operated by the MRC, the Addfield C1000, when in operation, will be working 24 hours a day for more than 330 days a year (estimated to reach 8000 hours per year), to dispose of much of the waste generated by hospitals and health centres across Kuwait.

Built to meet the customer requirements

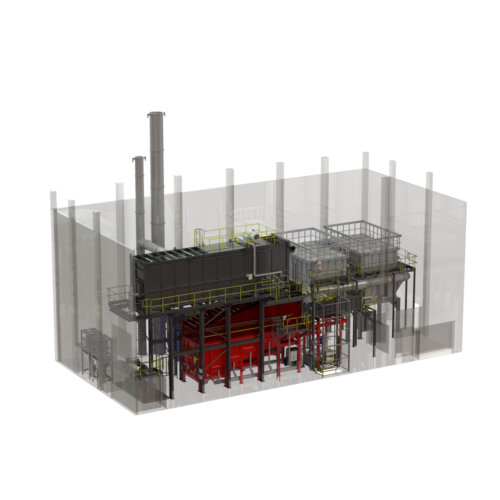

After carefully reviewing the requirements and composition, our team of design engineers began developing a state-of-the-art facility. Specifically engineered, this Addfield-built plant took over 2000 hours to design specifically for the client. Fully understanding the facilities’ workflows, waste types, and challenging geographical weather conditions.

For this project, it was agreed that the most suitable machine was a stepped hearth C1000. Standing at over eight metres in height, this automatic waste management system incorporated an integrated weighbridge, bin lifter and sequential waste charging system. Capable of lifting 1000+ litre bins and decanting waste directly into the charger before being delivered into the stepped hearth primary chamber.

By the time the bin tipper reloads the charger, the previous load of waste will be automatically transferred to the lower hearth staging. This movement creates a hostile environment and provides the conditions to oxidise the hazardous waste thoroughly. As it traverses the combustion chamber, the waste is reduced in size, eventually to a fine, inert ash. Resulting in the overall volume of the waste being approximately less than 5% of the original volume of clean and safe to dispose of ash. After the final step, the ash is then removed continuously and automatically through a conveyor system.

Safer for the environment

To provide maximum results, the primary chamber has been specially configured to operate under starved air conditions. This directs the partially burnt gases given off by the waste into the secondary after-burning chamber. These gasses then travel through a turbulent and high-temperature environment for the thorough treatment and oxidation of all flue gases that are produced during the incineration process.

Weighing in at over 10 tonnes, the C1000 secondary chamber is the first step of cleaning with an initial two-second retention time as required by legislation. Once the gasses have been directed through the secondary chamber, energy is recuperated in the form of hot water. Then a series of reagents are used, specifically, Sodium bicarbonate-activated carbon powders and urea solution. Injected directly into the flue gas stream, the treated flue gases then pass through the dedicated filter house incorporating a bank of ceramic filter elements. Collecting and discharging any remaining air pollution control residue. These are automatically discharged into collection bags/skips below.

The C1000 exhaust system benefits from having a variable speed-induced draught fan to draw the gases through the entire process before finally directing them to an enormous dedicated chimney. This exhaust system is fitted with an accredited and WID/IED-compliant continuous emission monitoring system independently linked to the control room-based SCADA system. This gives a permanent and constant record of all flue gas emissions to the atmosphere, this is vital when disposing of such high quantities of medical waste every hour.

Finally, adding an additional level of environmental sustainability to this installation, the waste heat recovery boiler provides a constant supply of clean hot water, which is used across the entire complex infrastructure.

Construction throughout Covid

Work originally began in February 2020 just as the Coronavirus was making itself known. Despite the challenges brought by several lockdowns and increased difficulties in resource management, the construction took shape over the next 18 months until November 2021 when after completing a full Factory Acceptance Test. Taking the machine through every stage of the cycle and checking each element. Only once a machine such as this passes all its tests is it ready to go. And so over several days and multiple heavy-load capable wagons, the C1000 was shipped out to Kuwait.

By February 2022 all sections and components were in place for our team of engineers to travel to Kuwait to begin what would turn out to be a 6-month installation due to its size and complexity. Overseeing the entire project our team of expert engineers worked side by side with local engineers and operatives from Kuwait to put the facility into operation. Having an expected operational life of over 20 years Addfield will ensure that the entire system is capable of being operated and maintained in-country. Delivering a fully comprehensive program of operation and maintenance training for local engineers during the final installation and commissioning stage.

MRC chose to work with Addfield after carefully reviewing other manufacturers from England, France, Germany, and the USA. The decision was in part due to the recognition of our reputation in this arena for delivering consistent high-quality solutions for large incineration facilities internationally.

During the later stage of construction, we had the honour of welcoming a full delegation from Kuwait of senior business people and ministers. Traveling nearly 3000 miles to complete their due diligence and meet the team behind this project as well as to discuss future opportunities.

Seeing their machine being put together in the factory and witnessing the skill and craftsmanship that goes into every element is important for our customers to reinforce their decision. It’s one of the most commented on elements when we have visitors to the factory that they are able to see where their new machine is being built and also meet the people that will be building it.

This has been another fantastic project for us to work on and recognition not just of the quality of work that we deliver at Addfield. It is also the confidence that made in Great Britain still carriers around the world. Another clear investment in the quality and reliability of British Manufacturing, as celebrated by the Department for International Trade ‘Exporting is Great’ initiative.