G20 (20Kg/hr)

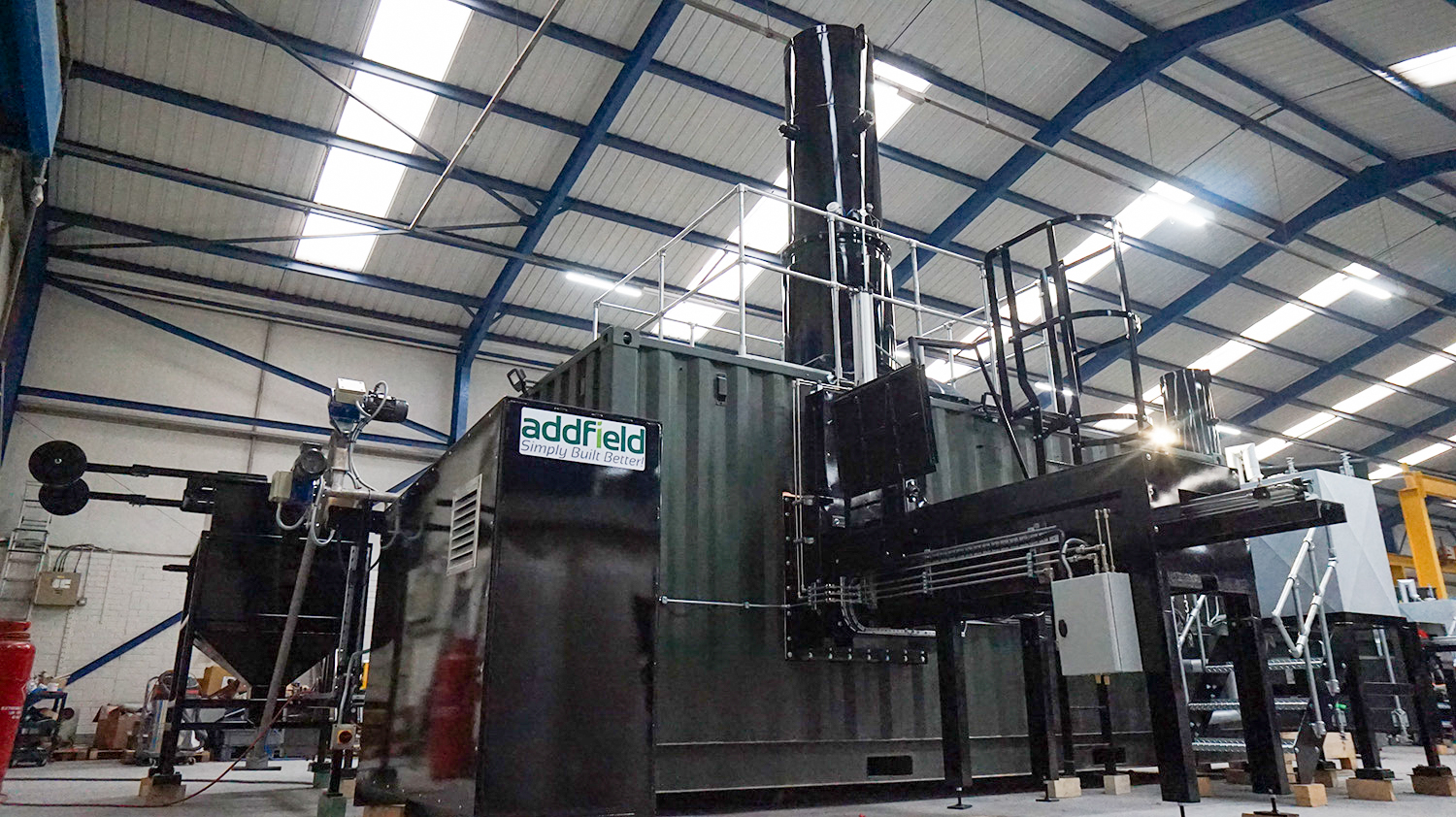

Mining Waste incinerator the Addfield G20.

The G20 Mining waste incinerator is one of the more unique solutions to general and mixed waste disposal. Designed to process low density and high energy clinical waste at a burn rate of up to 20kg/hr. Alongside disposing of contaminated sand and soil for mining and oil camp sites.

Benefiting from a large primary chamber specifically designed for loads that could contain high volumes of plastic. The cylindrical chamber with its four burners optimises airflow and directs the heat energy directly to the heart of the waste allowing this to be incinerated in a very efficient manner.

As the G20 is capable of managing general mining waste which could contain high levels of plastic it benefits from having a large 4.3m3 primary chamber. In this instance, the primary chamber is rounded which helps to eliminate any cool spots and actively encourages the optimal circulation of energy inside the chamber. Additionally, the G20 benefits from a specially adapted floor which improves the air injection below the waste alongside having an additional air curtain above the waste this circulates the oxygen throughout the chamber which ensures a stronger burn cycle and reduces the amount of fuel required.

The G20 is available in freestanding and containerised options. Coming with a ram charger to manage the loading of general campsite waste. Additionally, contaminated materials can be loaded via a screw feed system leading to its unique refractory designed to allow loading of highly flammable waste in a controlled and safe manner.

The advanced design and construction is perfectly accompanied by a user friendly and easy to use operation. Using the custom Addfield HMI touchscreen control panel, which enables the machine to operate on a virtual ‘One Button’ operation. The G20 comes with the additional benefit of data-logging as standard. This enables the monitoring of performance and how it reacts with your unique composition of waste to make sure that it is burning successfully.

At the end of each cycle, the remaining ash residues (typically less than 3% of the original volume) can be safely removed prior to the next load being entered and the cycle repeated once again.

The G20 has been carefully designed to deliver maximum results for remote mining camps, oil and gas camps and complex installations that need a reliable high-capacity solution to safely dispose of potentially hazardous waste of all types.

Operating along the same principles as all Addfield machines incorporating a primary loading chamber for incinerating the waste leading to a secondary chamber, which further processes any gasses with a two-second retention time enabling for an environmentally sustainable smoke and odour free operation. A number of more advanced filtration systems are also available including a Venturi wet scrubber system. This need for advanced filtration will depend upon the categories and nature of clinical waste that you will be using your G20 to dispose of and the final country of installation. You can discover more about your options by visiting the Filtration section of the website by clicking here.

As with all Addfield incinerators the G20 has been designed and manufactured to meet and exceed many of the world’s strictest regulations to ensure a sustainable operation for many years to come. CE certified and adhering to full EU and World Health Organisation standards. Each machine is fully manufactured in Great Britain, to an extremely high standard. Constructed from heavy gauge steelwork and a multi-layered brick-lined refractory for maximum efficiency and longevity.

If you have any further questions or you would like to come to the factory and view the machines yourself just contact us on +44 01543 571280 or email sales@addfield.com.

- British Designed.

British Built. - World leaders in

incineration technology. - Unrivalled build quality

& machine longevity. - Distributed to more

than 150 countries. - Environmentally

Responsible. - Trusted partner, over

40 years experience.