07/01/19

A unique insight into waste management at remote locations.

We have just discovered a fantastic article online detailing the ongoing issues with dealing with waste produced on remote islands.

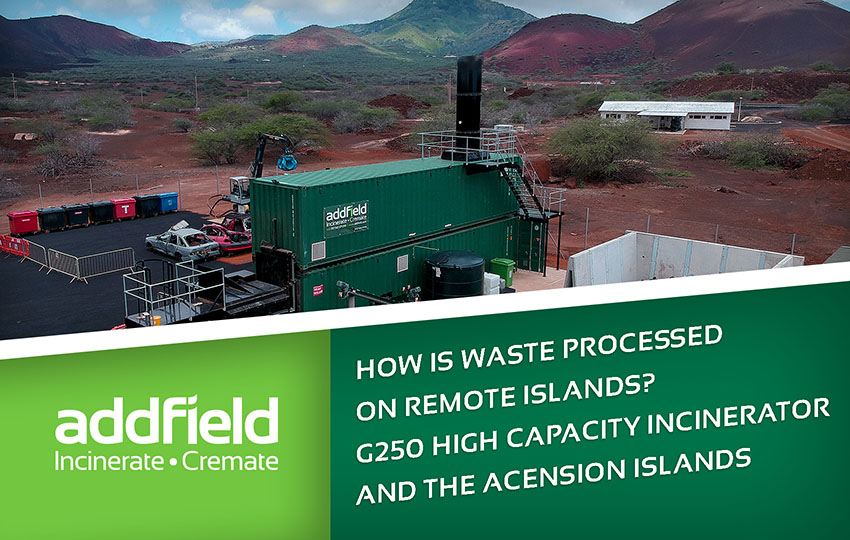

As we have been sharing the ongoing development of our G250 high capacity incineration plant for the Ascension Islands which is now installed and operational. This article details the issues on St Helena and the neighbouring, yet still many miles away Ascension Island.

Written from the personal viewpoint of a resident of St Helena this provides a profound insight into what living in a remote location is actually like for disposing of waste.

“For years, Ascension household waste has been collected, taken to their waste site, tipped out and then (with the help of a box of fire lighters) burnt in an open heap. The residue of the burnt waste (predominantly steel and aluminium cans, and glass bottles) is then landfilled. The open burning removes most of the paper, cardboard, food waste and plastics, which equates to c.90% of the total waste volume and prevents any subsequent build-up of methane gas as the organic material decomposes. Open burning is far from ideal – it’s unsightly, inefficient (as all the combustible material is not burnt) and extremely ‘dirty’, with clouds of black smoke containing noxious gases from the large amount of plastics. You can see the black stain across the landscape on Google Earth.” Leigh Morris

This really brings home the reasoning behind installing a solution such as the G250 which will now provide a genuinely safe and clean way of disposing of waste that cannot be recycled.

The article also highlights a number of key recycling strategies that could be implemented on the islands in the future.

“Aluminium drink cans are worth c.£1000/tonne (a beer can weighs 20g, so is worth 2p when baled. 50,000 cans in a tonne – Mike and I worked this out one evening in his kitchen in-between games of darts!) and you can apparently load 17 tonnes into a shipping container. So, if it costs £5k to get the container to the UK, that gives c.£12K profit on the shipment, which would more than cover the collection and crushing. It might take some time to fill up a container with c.850,000 crushed cans, but it appears to be worth doing and, importantly, it keeps them from being land-filled.” Leigh Morris

It’s fantastic to learn the real impact that our machines can make for the environment in a way that many people may not generally be aware of. We have a number of additional high capacity installations in production, including one project specifically for treating 2 tons of plastic waste an hour.

- British Designed.

British Built. - World leaders in

incineration technology. - Unrivalled build quality

& machine longevity. - Distributed to more

than 140 countries. - Environmentally

Responsible. - Trusted partner with

40 years experience.