21/06/18

Sustaining the natural beauty on the Ascension Islands.

It’s a fantastic honour to have been asked to provide a solution to The Ascension Islands. A beautiful location just south of the equator. An incredibly remote location, with a population of approximately 800 people including a US Airforce base housing 200 residents. Being surrounded by so much ocean and with a limited amount of land means that solid waste is a serious issue that needs to be addressed to prevent damaging the environment on and off the island.

We already have a lot of previous experience in providing waste incineration solutions for several island locations. Making us perfectly suited to deliver the right solution for their mix of waste produced. Even with a relatively manageable population manmade waste has to be disposed of carefully to prevent potentially hazardous contamination. An installation such as this needs a machine that is specially optimised to handle the full mix of the waste generated on the island.

Our solution is one of our high capacity incinerators the G250. Built inside two 40ft containers, this self-contained machine minimises the civil work required on site for installation. For a project this remote it greatly reduces the challenges of installation, handling and logistics. The G250 has automatic loading and a stepped hearth to allow safe continuous loading throughout the incineration process. Capable of processing 250kg of waste every hour. The G250 is able to ensure a clean incineration of mixed waste types through its large cylindrical secondary chamber with a two-second retention to ensure that only clean flue gas is returned to the environment. It has been built to effectively process all waste that the Islanders will put into it, including medical waste alongside organic, general municipal waste.

Accessing such a remote location is a challenge in itself. Nestled in the middle of the South Atlantic and surrounded by the greatest concentration of Great White sharks anywhere in the world. The quickest way to access the island is by plane. Although we will be shipping the machine by boat our engineers will be flying out which is not as simple as you may imagine as recently the weekly flights have been reduced to every three weeks, which means our engineers will be having an extended visit whilst installing and commissioning the machine.

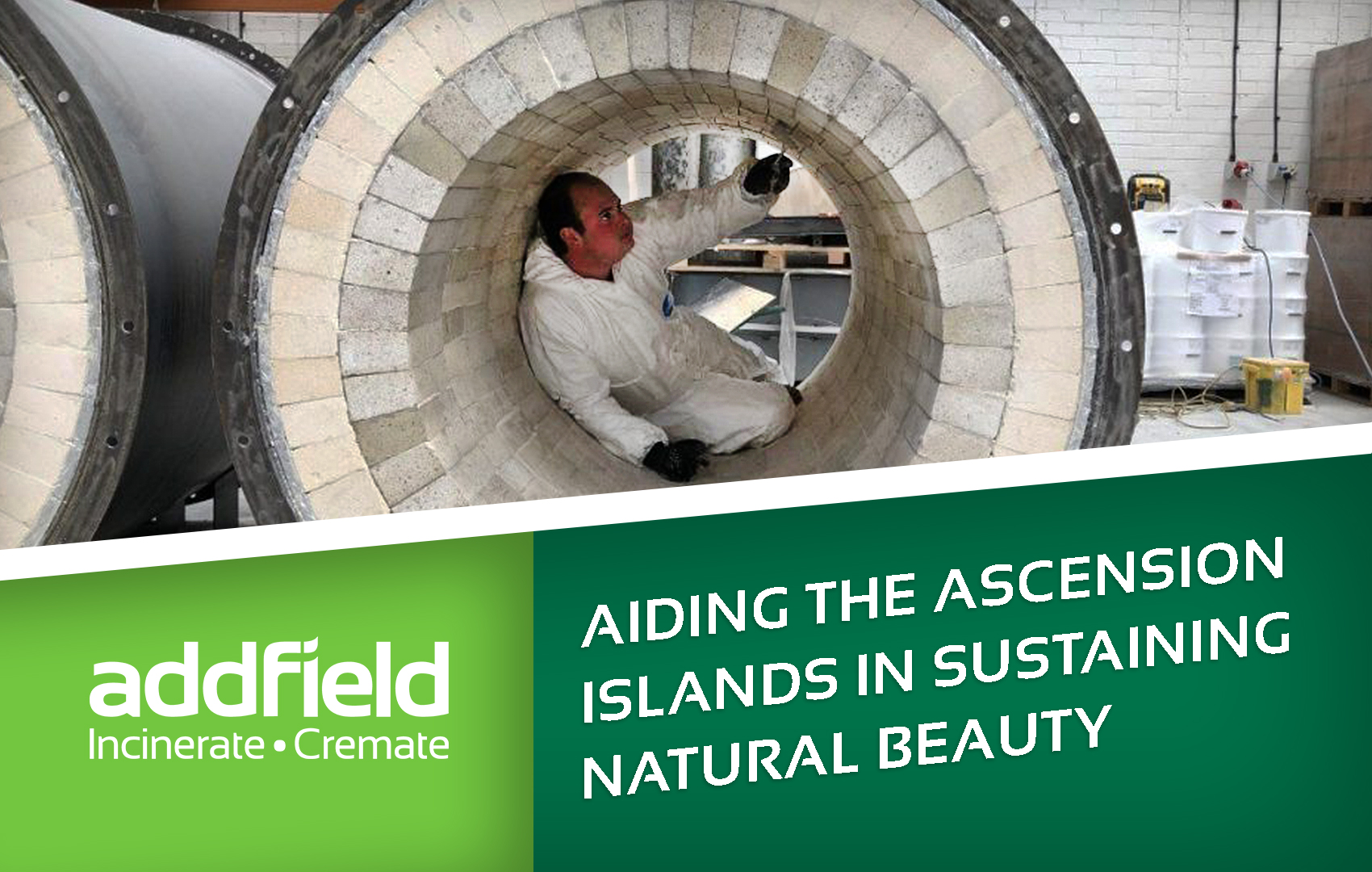

Reliability is essential in such a remote location which is why our machine was such a perfect match, our brick lined refractory, delivers incredible insulation, it also ensures that any damage from loading and sustained usage can easily be rectified compared to a completely concrete cast refractory. Any problems in the future with a brick refractory can be managed in a matter of days whereas a fault in a concrete cast refractory could put such a large machine in such a remote location out of action for months if not longer. Our engineers will be taking advantage of the extended installation time by fully training the locals in operating and maintaining such an impressive machine.

This has been a fantastic journey for all of us here working closely with the Government of the Ascension Islands through regular teleconferencing as well as their QA inspectors to ensure that with the help of our machine the islands are able to continue to be a natural haven undamaged by unwanted pollution.

Currently in production in our factory and a couple of months to go before delivery and commissioning we will keep you posted on how the machine is developing.

- British Designed.

British Built. - World leaders in

incineration technology. - Unrivalled build quality

& machine longevity. - Distributed to more

than 150 countries. - Environmentally

Responsible. - Trusted partner, over

40 years experience.